SLABS & TILE

Thin Stone 1cm Slabs

10x

Times Stronger, Two Thirds Lighter

1 CM SLAB

What Is Polycor’s Thin Stone?

Thin Stone is an ultra-thin reinforced slab of natural stone, cut down to 1 cm thickness, approximately 3/8” actual.

Thin Stone slabs are available in all of Polycor’s granites and marbles, each weighing 2/3 less than traditional 3 cm slabs.

1 cm slabs are backed with a proprietary reinforcement that gives the natural stone a Flexural strength 10 times that of thicker, unbacked granite or marble.

An Exclusive Polycor Innovation

1 cm slabs of natural stone combine durability and distinction: only one third the weight of a standard 3 cm slab, yet 10 times stronger.

This ultra-thin facing material is reinforced by a composite support and is available in 9’ x 5’ slabs. Entire walls, gigantic backsplashes, fireplaces, floating and integrated countertops: this product is perfect for any contemporary application.

Physical Benefits With Various

Applications

Aside from the aesthetics of the new 1 cm thin stone, if you’re a fabricator, installer or designer, you’ll also appreciate the physical benefits the material has to offer for various applications:

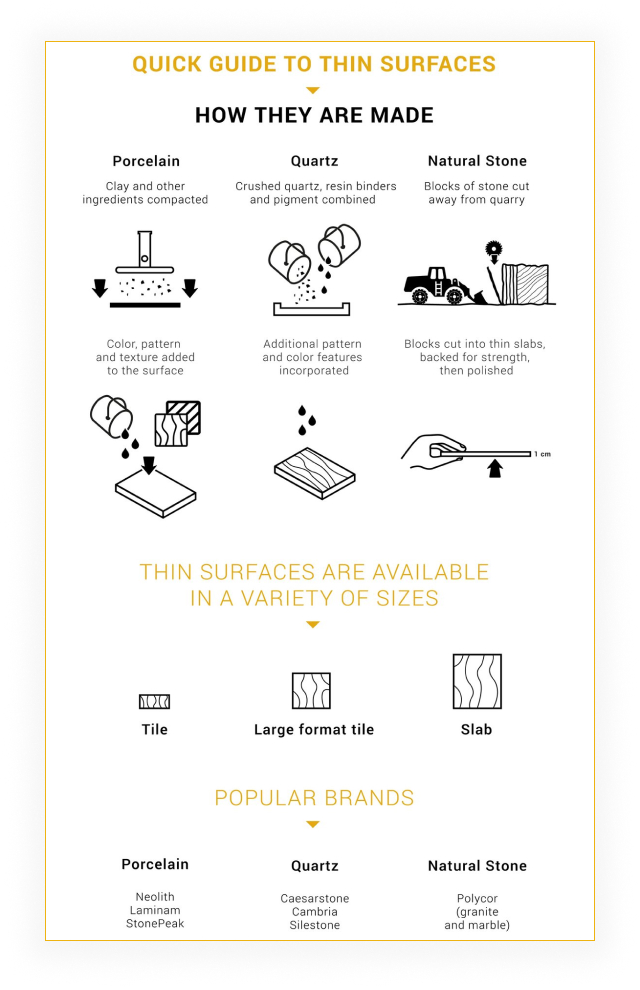

Quick Guide

How Thin Stone Slabs Are Made:

You can fabricate Thin Stone with typical shop tooling and stoneworking techniques. Use your usual tools for cutting, grinding, polishing and finishing. Match the blade to the material and cut at a slightly slower traverse speed than you would for a 2 cm stone.

A few key notes:

- No special tools are required for working with 1cm slabs.

- You’ll get more precise cuts with the same blade when cutting Thin Stone.

- Use water to cool the blade and prevent any chipping.

- Takes less time to complete the job and causes less wear on the tools, significantly preserving blade over 2 and 3 cm stone.

Video Resources: Polycor Spaces Series

FAQS

Fabricators Answered Top FAQs for 1 CM Thin Stone

The streamlined installation process of thin stone slabs provides multiple benefits for professional installers and project managers. Maneuvering finished pieces in tight spaces becomes significantly easier due to reduced weight and enhanced flexibility.

Structural load calculations are simplified, reducing engineering requirements and permitting complexity. Wall mounting systems require less structural support, expanding installation options and reducing costs. Read some of the top fabrication FAQ’s listed below…

Yes. The proprietary composite backing provides 10 times greater flexural strength than unbacked 3cm granite or marble, making it more resistant to cracking and structural failure.

Approximately 3/8″ actual thickness after processing and reinforcement backing application.

Yes, 1cm thin stone is available in all Polycor granite and marble varieties, including popular options like Cambrian Black, White Cherokee, Saint Henry Black, and many others.

No special tools required like there is for porcelain slab cutting and fabrication. Use your standard stone cutting, grinding, polishing, and finishing equipment. The main difference is significantly less tool wear and faster processing times.

Cut at slightly slower traverse speeds with abundant water for cooling the diamond blades. You’ll achieve cleaner cuts and can make single-pass cut-outs without back-cutting.

Yes, using standard stone polishing techniques. The process is actually faster due to reduced material thickness, with less time required to achieve desired finish levels. And there’s no need to re-tool your shop. Also, you aren’t required to miter edges like with porcelain which has a different interior color and composition than the face of the slab. Polycor 1cm stone slabs are solid stone, so you can simply polish an exposed edge.

Carrying them flat with the reinforced backing side down, or on edge is best. The composite backing allows safe flat transport of even full slabs, unlike traditional thin materials.

Two-component, epoxy-modified, cementitious mortars like Laticrete Latapoxy, Mapei Kerapoxy, or Granirapid for optimal bonding and long-term performance are preferred.

Yes, you can drill directly through the stone face without cracking concerns. The 3/8″ thickness makes catching framing members easy for secure mounting.

All standard edges work well: eased, rounded, bullnose, beveled. Both thin profiles and thick built-up mitered edges are possible.

Absolutely. Follow standard natural stone shower installation practices with appropriate waterproofing and substrate preparation.

Yes, thin stone is ideal for large format floor installations when properly supported with appropriate substrate systems.

Download complete Laticrete installation specifications and technical data sheets from our website, covering expansion joints, underlayment, and detailed procedures.

Contact Polycor’s technical support team or your local representative for project-specific guidance and troubleshooting assistance.

Yes, Polycor provides fabricator education and hands-on training opportunities. Contact us for information about upcoming sessions in your area.

Thin Stone 1cm Slabs

Thin Stone 1cm Slabs

Download the 1CM Natural Stone Fabrication Guide

Quick Guide

How to Fabricate Polycor 1 CM Ultra Thin Stone

An exclusive Polycor innovation, 1 cm slabs of natural stone combine durability and distinction: only one third the weight of a standard 3 cm slab, yet 10 times stronger.

This ultra-thin facing material is reinforced by a composite support and is available in 9’ x 5’ slabs.

Entire walls, gigantic backsplashes, fireplaces, floating and integrated countertops: this product is perfect for any contemporary application.

Get the Guide

Thin Stone 1cm Slabs

Download the 1CM Natural Stone Fabrication Guide