American Stone Quarries

Locally Quarried, Processed, and Delivered Within America

For over 150 years, American stone has built the foundation of our nation’s most treasured structures. From the Empire State Building to the National Cathedral, the story of American architecture is written in stone. Today, that same tradition continues at Polycor’s quarries and plants located across the U.S. in locations such as Vermont, Indiana, Georgia, and beyond.

Polycor’s extensive network of domestic quarries represents the finest dimension stone deposits in the nation, enabling the delivery of exceptional quality with unmatched reliability. Choosing American-made stone means investing in materials with documented provenance, consistent availability, and significantly reduced lead times.

By controlling the entire supply chain within America’s borders — from extraction to fabrication and delivery — we eliminate international shipping delays, bypass customs complications, and provide greater predictability of timelines for your projects. This comprehensive domestic approach allows us to complete even the most ambitious installations ahead of schedule, as demonstrated by successful projects across the country.

The American Advantage

Supply Chain Control: Seamless Operations from Quarry to Project Site

When you choose Polycor American stone, you’re getting more than premium materials, you’re getting an accountable partner that manages every step of the process. Our quarries and manufacturing facilities work together seamlessly, streamlining processes, continually improving efficiencies, and eliminating unpredictability.

Cut That Lead Time By An Ocean: No International Delays

Our domestic operations eliminate the months of delays associated with international shipping. While imported materials can face indeterminate delays, American-made Polycor stone moves directly from quarry to fabrication to your project site. This integrated network consistently delivers projects on schedule.

Consistent Quality: American Craftsmanship Standards

Every block extracted from our American quarries undergoes rigorous quality control testing to meet or exceed industry standards. Our skilled craftsmen, many representing generations of quarrying expertise, ensure that each piece meets Polycor’s exacting specifications for dimensional accuracy, surface finish, and structural integrity. Every stone has detailed ASTM test data that provides transparency and accuracy for the most demanding specifications and applications.

Reliable Availability: Extensive American Quarry Reserves

Our American quarries, some in operation since the 1800’s, contain millions of cubic feet of proven reserves, ensuring consistent material availability for projects of any scale. This domestic abundance means you can confidently specify Polycor stone knowing that it will be available at the time the project needs it to land, as well as for future phases or maintenance needs where matching stone may be required.

Cost Predictability: Avoid International Fluctuations

American-made stone eliminates the cost uncertainties associated with international trade. No tariffs, no exchange rate fluctuations, no unexpected shipping surcharges. This predictability helps keep your project budgets on track and protects against the economic volatility that can impact imported materials.

Supporting American Economy: Investing in Local Communities

When you choose Polycor American stone, you’re supporting domestic manufacturing jobs and investing in the skilled trades that built, and continue to build, America’s architectural heritage. Our quarries and fabrication facilities provide stable, well-paying careers while contributing to the economic vitality of American communities.

Gallery

Government Projects Featuring Polycor American Stone

Historic Preservation Success

American stone continues to play a vital role in preserving our architectural heritage. Recent restoration projects using matching stone from the original quarries that supplied iconic projects, such as Georgia marble and Indiana limestone, demonstrate how domestic quarries can provide historically accurate materials for maintaining America’s most important buildings well into the future.

Commercial Project Excellence

Large-scale commercial installations from coast to coast rely on American stone for timeline certainty and quality assurance. Projects ranging from corporate headquarters to educational institutions benefit from the predictable supply chain that only domestic production can provide.

Polycor’s American Quarry Network

Indiana Limestone Quarries – Bloomington and Bedford, Indiana

The heart of American limestone production, our Indiana operations have been quarrying premium building stone since the 1880’s. Extracting approximately 3 million cubic feet annually, these quarries produce a wide range of colorful limestone, including INDIANA LIMESTONE – FULL COLOR BLEND™ and INDIANA LIMESTONE – STANDARD GRAY™ that grace everything from the Empire State Building to residential backyard paver patios across the nation.

Indiana limestone’s unique geological formation creates stone with exceptional workability and weather resistance. The consistent grain structure and natural variation in warm buff colors and medium gray tones make it ideal for both historic restoration projects and contemporary architectural applications.

The quarrying process involves careful block extraction in sizes ranging from 4 to 12 feet in length, 3 to 8 feet in width, and 2 to 6 feet in height. Both open-pit quarrying methods and some underground extraction operations are in place, depending on the specific location and geological conditions.

The combined facilities process thousands of cubic feet of limestone monthly, with the ability to handle major commercial and institutional projects, as well as supply hardscape and masonry stone yards across the nation with a wide range of finished products.

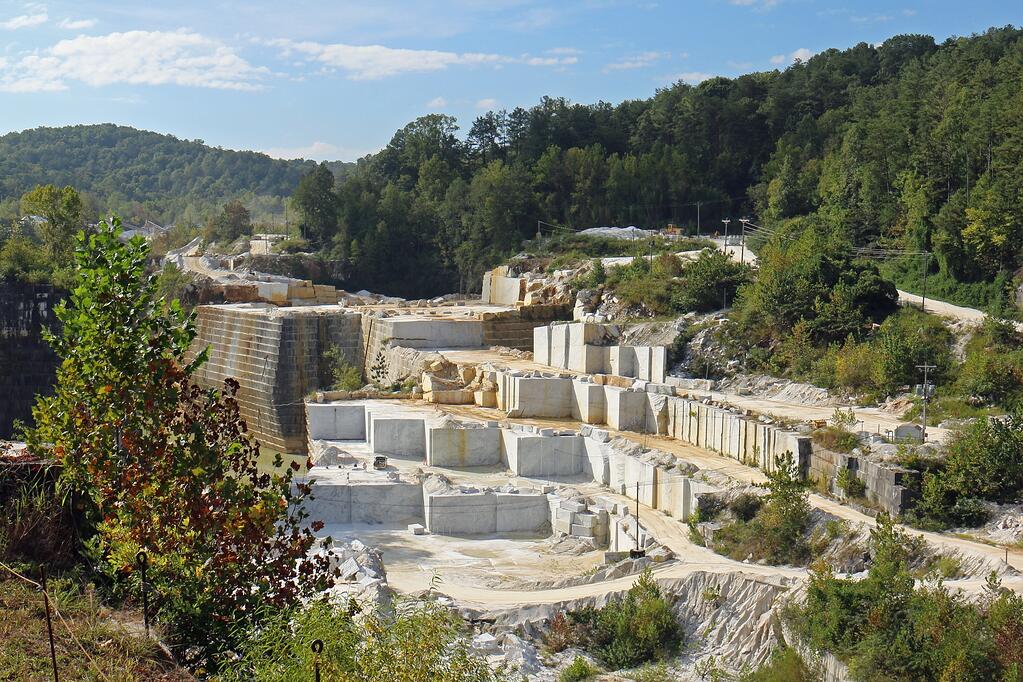

Georgia Marble Quarries – Tate, Georgia

Operating since the 1840’s, Polycor’s Georgia marble quarries north of Atlanta, in Tate, produce some of the world’s finest marble. The extensive deposits yield multiple varieties of marble, including GEORGIA MARBLE™ – WHITE CHEROKEE™ and GEORGIA MARBLE™ – PEARL GREY™. The marble from this region has been specified for iconic projects, including the Lincoln Memorial, the U.S. Capitol Building, and countless prestigious commercial and residential installations throughout America.

The unique geological conditions in North Georgia create marble of an exceptional density and purity. It is known for its sparkling, crystalline calcite structure and a superior performance that make it a highly sought-after material for demanding applications from high-traffic commercial floors or facades, and elegant residential countertops.

The Georgia marble belt extends for several miles through the region, with the Tate quarry being one of the most significant operations. The marble occurs in massive beds that can extend 200+ feet in depth. The facilities maintain capabilities for both modern architectural applications and historical restoration work, often matching existing Georgia marble installations in buildings throughout the nation.

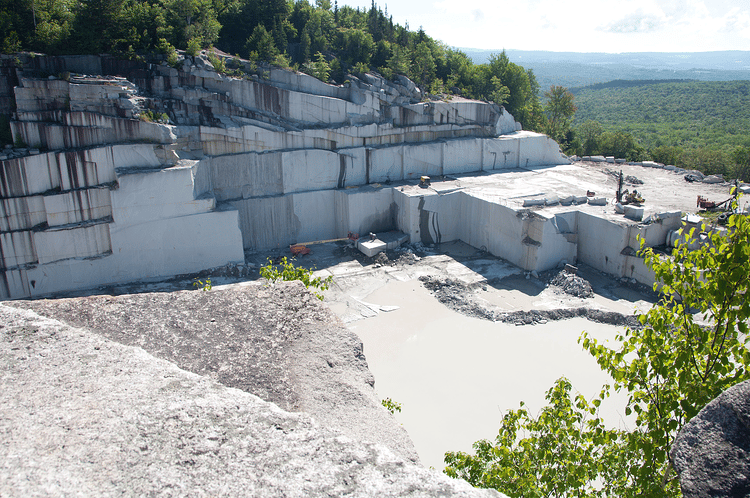

Vermont Granite Quarries – Barre, Bethel, and Woodbury, Vermont

Vermont’s Granite Belt has been synonymous with high-quality stone containing some of the world’s finest granite deposits and the site of quarrying operations dating back 150 years. Polycor’s Barre and Bethel operations produce WOODBURY GRAY™ and BETHEL WHITE™ granites prized for their exceptional strength, weather resistance, and consistent appearance.

The BARRE GREY™ granite quarries are among the most famous in North America, with the E.L. Smith Quarry site operating the largest active granite quarry in the world. It is an impressive open-pit operation that extends over 50 acres and reaches depths of 600+ feet, which could hold 2 Statue of Liberties stacked on top of each other.

These quarries benefit from some of the world’s most favorable geological conditions for granite formation, creating stone with remarkable durability and workability that has made Vermont granite the choice for monuments, commercial facades, and hardscape applications nationwide.

Other Granite Operations

Polycor manages and operates many other granite quarries and plants, including in Jay, Maine, as well as Elberton, Georgia, and Elverson, Pennsylvania, all of which expand the tradition of American granite quarrying. Combined, there are generations worth of stone craftsmen who have helped build American history with their expertise and skills.

Stones from these locations include AMERICAN BLACK™, JAY WHITE™, and ELBERTON GRAY™ granites.

Discover Our American Stone Collection

Indiana Limestone Collection

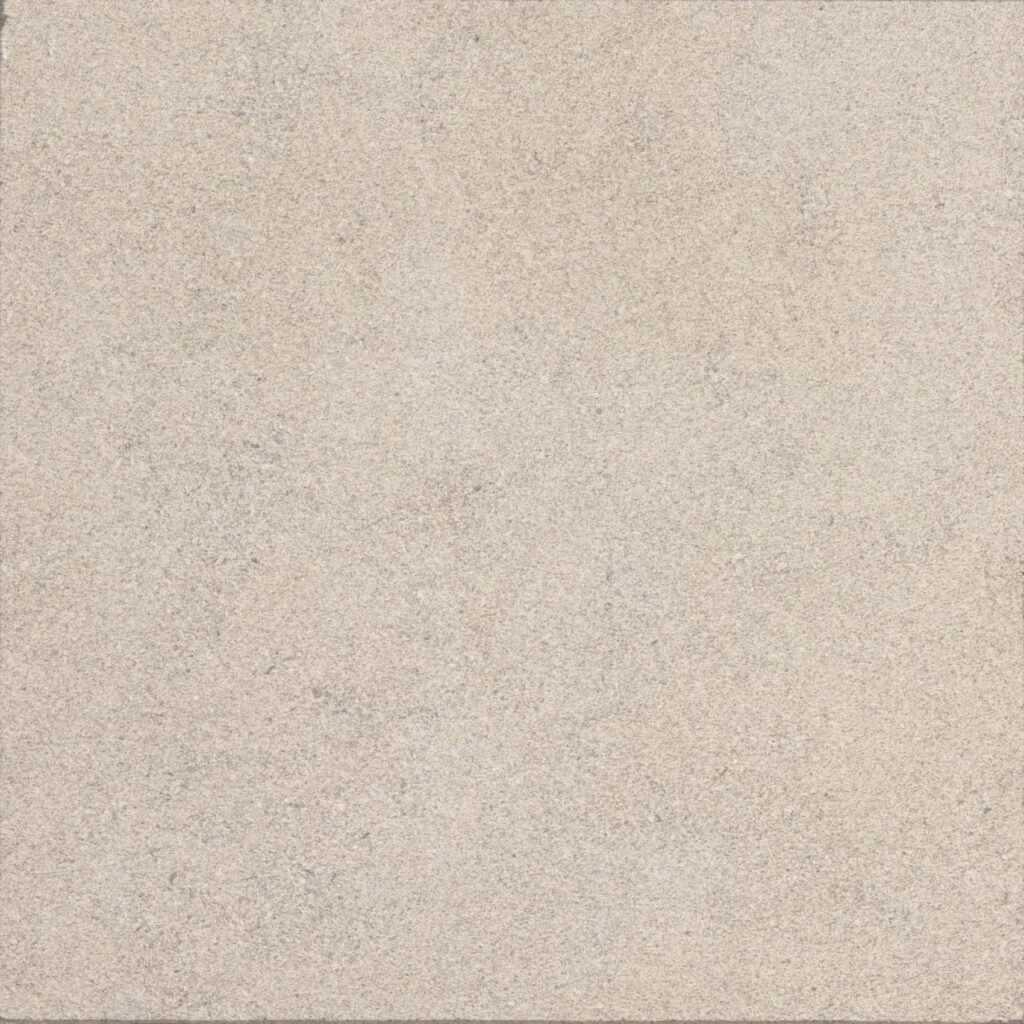

INDIANA LIMESTONE – FULL COLOR BLEND™ This material is considered America’s original building stone, offering a natural compilation of warm buff colors and medium gray tones. Its dense, compact grain structure provides marble-like quality while maintaining limestone’s superior workability and weather resistance.

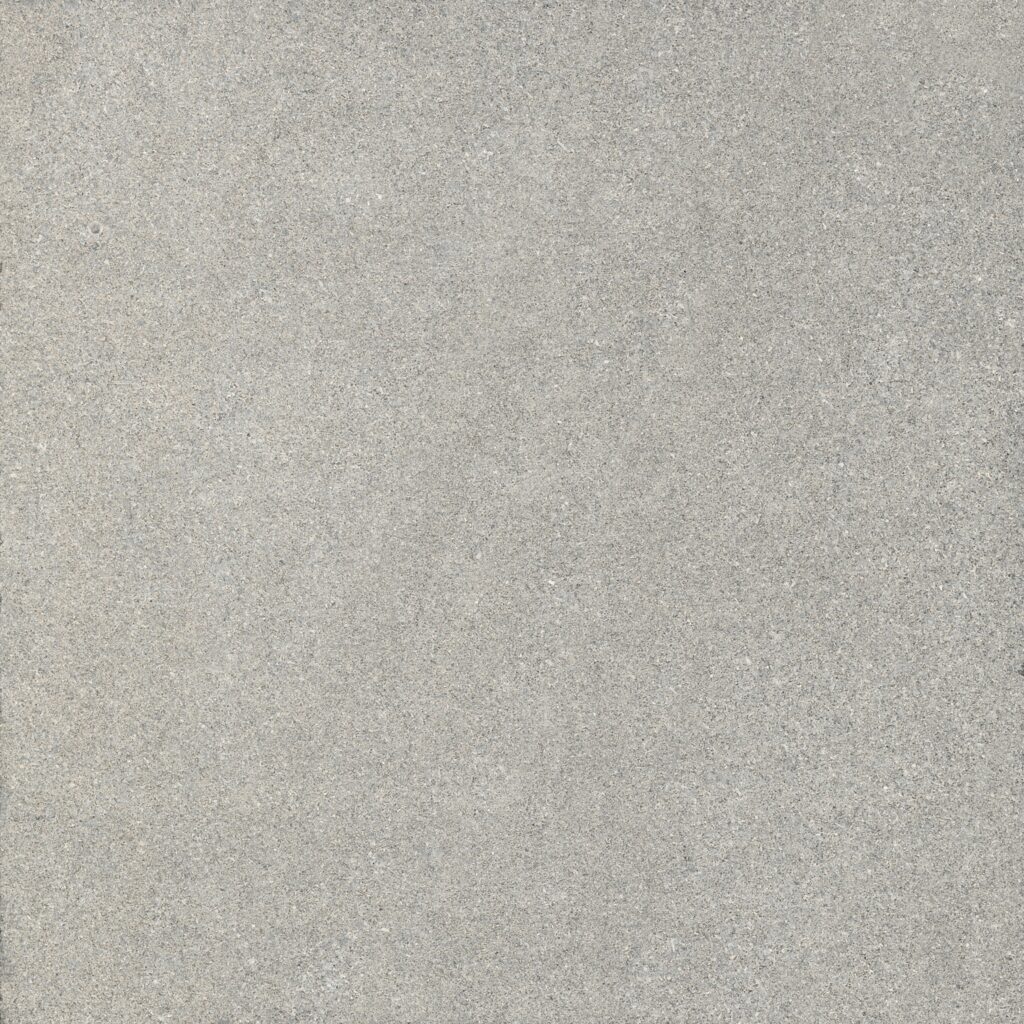

INDIANA LIMESTONE – STANDARD GRAY™ This neutral limestone possesses a subdued palette featuring light to medium shades of gray. A restrained, underlying vein pattern and subtle grain movement are visible in the fine to medium-grained surface.

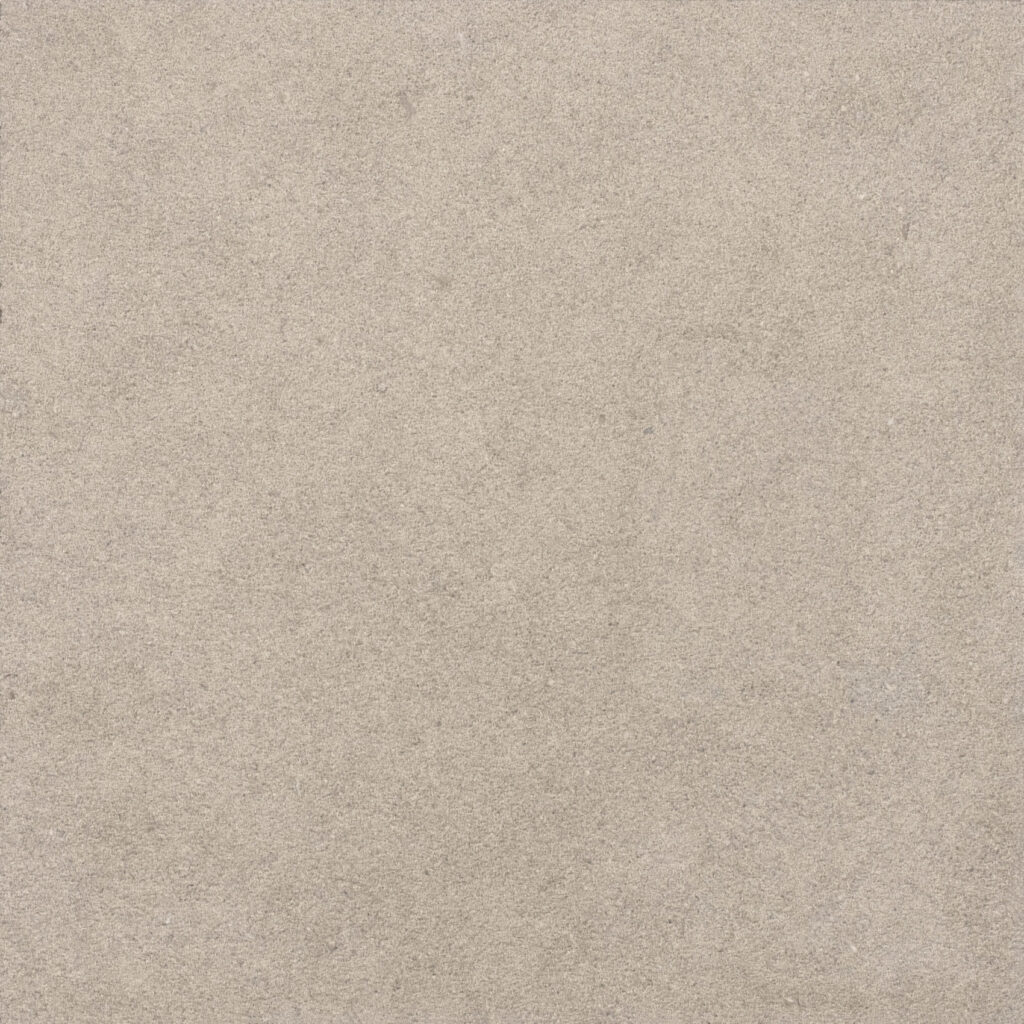

INDIANA LIMESTONE – RUSTIC BUFF™ This traditional buff colored limestone ranges in hue from warm cream to light brown, all with a visible vein movement throughout the surface. The medium to coarse-grained composition exhibits unique inclusions for a variegated appearance.

INDIANA LIMESTONE – STANDARD BUFF™ This traditional buff shade of Indiana Limestone ranges from a warm cream to light brown with muted veining and slight grain movement visible in the surface. Its fine to medium grain composition make it a prized material for architectural ornamentation on iconic buildings across North America.

INDIANA LIMESTONE – STANDARD SILVER BUFF™ A neutral, cool gray buff limestone featuring subtle silver colored veining in the foreground and a fine to medium-grained mineral structure.

INDIANA LIMESTONE – RUSTIC GRAY™ A medium to large-grained limestone keeping within a gray tonal range of light to medium gray shades that exhibits unique features and fossilized inclusions for a neutral, subtly veined, and rustic aesthetic.

Georgia Marble Collection

GEORGIA MARBLE™ – WHITE CHEROKEE™ One of America’s most homogeneous marbles, White Cherokee has been the choice for large architectural projects and heritage building restorations for over a century. Its consistent white background and subtle gray veining create timeless elegance.

GEORGIA MARBLE™ – PEARL GREY™ This marble features distinctive white, gray, and black veining that creates dramatic visual interest. The consistent grain structure contributes to exceptional strength and weather resistance, making it suitable for both interior and exterior applications.

GEORGIA MARBLE™ – SOLAR GREY™ This homogenous and closely-packed marble features a variable gray and black vein distribution. It has excellent durability in indoor and outdoor architectural applications.

Vermont and New England Granite Collection

WOODBURY GRAY™ This exceptional granite from Vermont quarries features a medium gray color with consistent patterning. The balanced mineral composition creates excellent workability while maintaining the superior strength that granite is known for.

BETHEL WHITE™ A bright white granite with subtle speckling, Bethel White offers contemporary appeal with traditional New England quarrying heritage. Its clean appearance and exceptional durability make it ideal for modern architectural applications.

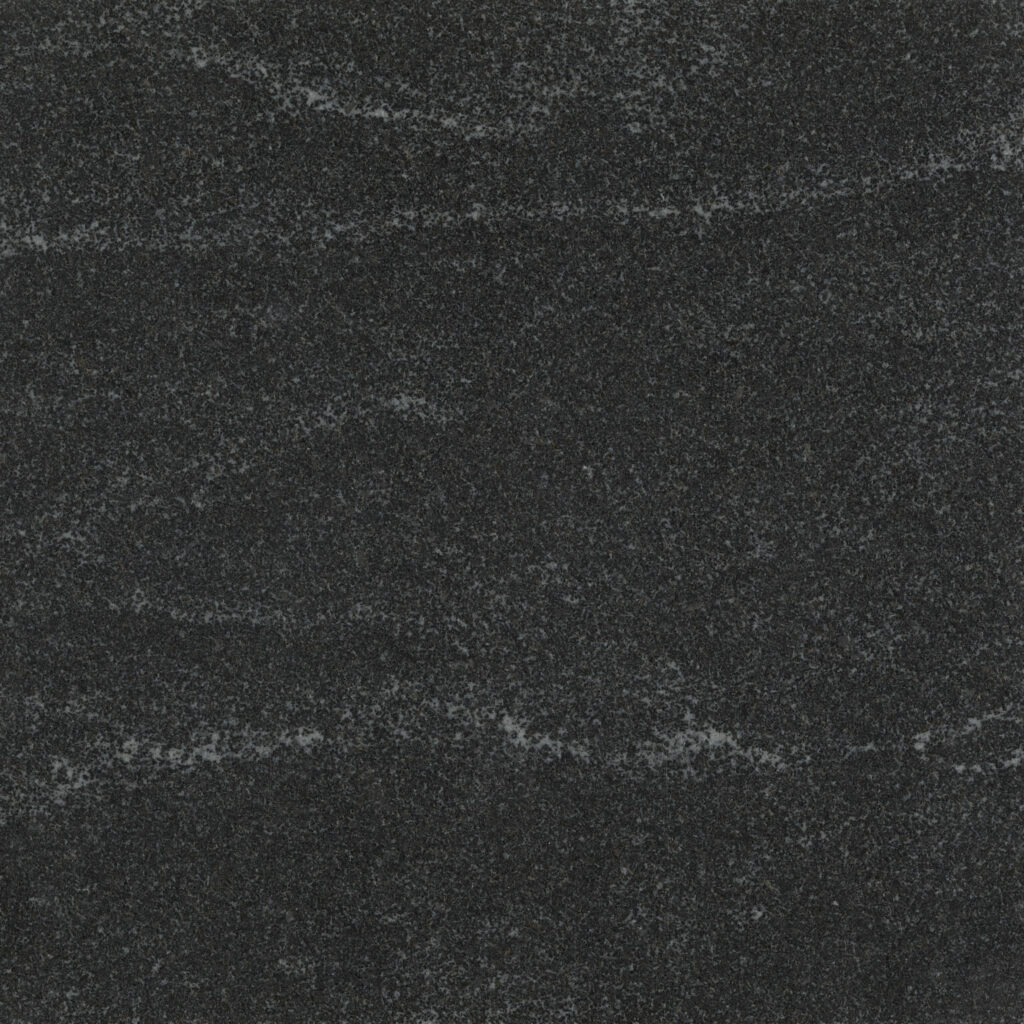

AMERICAN BLACK™ and AMERICAN MIST™ These dramatic granites showcase the full range of American stone capabilities, from deep blacks to sophisticated patterns that add visual interest to any application.

From Raw Blocks to Finished Products

Advanced American Manufacturing Facilities

Our American manufacturing network includes state-of-the-art fabrication facilities strategically located near our quarries. The Eureka Plant in Indiana, Empire Plant operations, and Georgia Marble Plant combine cutting-edge technology with traditional craftsmanship to produce finished stone products to exact specifications.

Technology Meets Tradition

Modern diamond wire cutting systems, multi-axis CNC fabrication equipment, and precision finishing tools ensure consistent quality while maintaining the artisanal attention to detail that has defined American stone craftsmanship for generations. This combination of advanced technology and skilled expertise enables Polycor to meet the demanding timelines of contemporary construction while maintaining the high-quality standards that have made American stone legendary.

Fabrication Capabilities

Our American plants can handle projects of any scale, from single residential installations to massive commercial developments. Custom cutting, specialized finishes, and precision fabrication ensure that every piece meets project specifications precisely, reducing installation time and eliminating the need for field modifications.

A Proud American Quarrying Heritage

Building America’s Architectural Legacy

Walk through any American city, and you’re walking through a story written in stone. The U.S. Capitol Building, Grand Central Terminal, countless courthouse squares—American stone has literally built the foundation of our nation’s most treasured structures. For over 150 years, Polycor’s quarries have been integral to this heritage, supplying stone for iconic buildings that have stood for over a century and continue to inspire architects and builders today.

This proven performance record demonstrates not just the quality of American stone but the reliability of American quarrying expertise.

Preserving local jobs

Helping community programs

Responsible production methods

Timeline of American Excellence

- 1880’s: Indiana limestone quarries begin large-scale operations

- 1890’s: Georgia marble quarries expand to meet growing demand

- 1900’s: Vermont granite operations establish national reputation

- 1920’s-1930’s: American stone increaskingly specified for major federal buildings

- 1950’s-1960’s: Modernization of quarrying and fabrication techniques

- 1980’s-Present: Polycor consolidates and modernizes American operations

- 2020’s: Renewed focus on domestic supply chain advantages

Preserving Traditional Skills

Our American operations maintain the skilled workforce that represents generations of quarrying knowledge. Master stone cutters, experienced quarry operators, and skilled fabricators pass their expertise to new generations, ensuring that American stone craftsmanship continues to evolve while preserving time-tested techniques.

Case Studies

American Stone Success Stories

Institutional Excellence: Freedom Place at Old Parkland

Freedom Place at Old Parkland in Dallas exemplifies how American stone delivers both architectural excellence and practical advantages for major institutional projects. This 7-story, 210-foot-tall structure required 78,000 cubic feet of INDIANA LIMESTONE – FULL COLOR BLEND™ to create a neoclassical addition that seamlessly integrates with the campus’s historic Jeffersonian architecture.

Originally specified with cast stone, the project team switched to American limestone mid-design after recognizing the superior value proposition. The natural stone option delivered significantly enhanced durability, sustainability benefits, and the ability to fabricate larger pieces with fewer joints.

The domestic supply chain proved crucial to meeting the project’s ambitious timeline. With Polycor’s Indiana quarries providing consistent material availability and streamlined logistics, the team completed the stone installation in just 9 months, welcoming President George W. Bush into the finished building on schedule.

This project demonstrates how American stone enables architects to specify larger, more impressive elements while maintaining cost competitiveness and timeline certainty that only domestic production can provide.

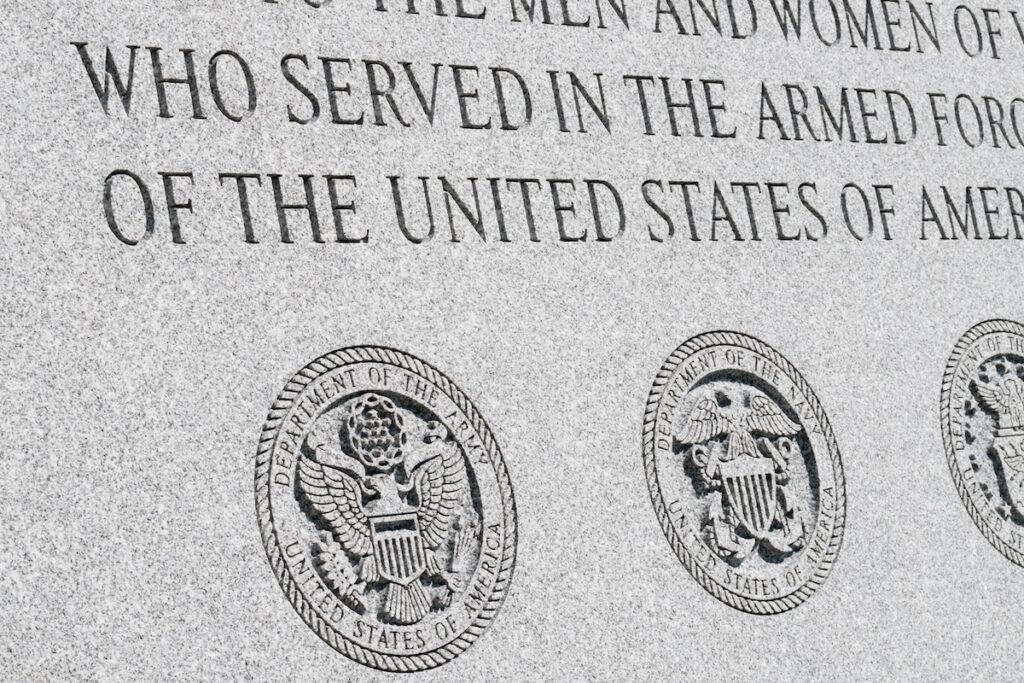

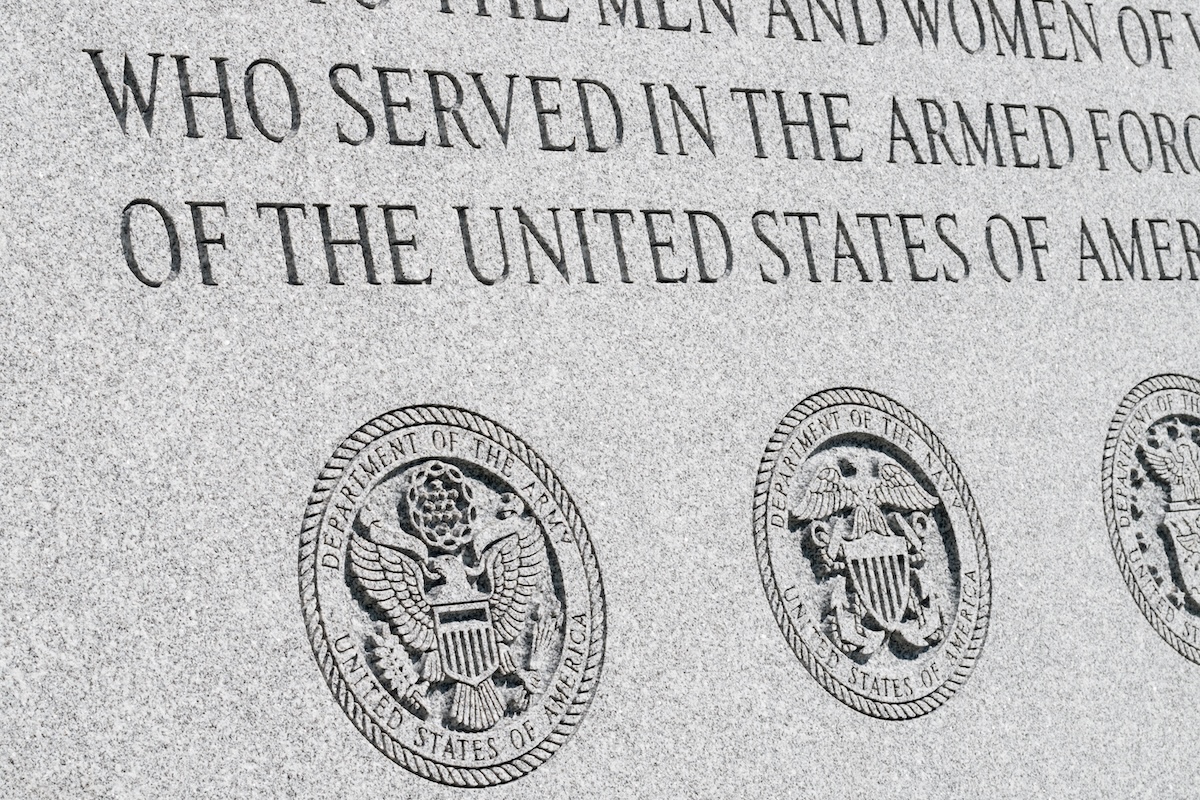

Honoring America’s Heroes: Memorial Projects

American stone has played a central role in creating lasting tributes to our nation’s service members and civic heroes. At Polycor, we share the same values of our military veterans: devotion, generosity, and commitment. Our American quarries have supplied premium granite, limestone, and marble for hundreds of Veterans War memorials and installations in VA National Cemeteries across the nation. From the iconic Lincoln Memorial carved in Georgia marble to the Soldiers & Sailors Memorial in Indianapolis, as well as the Soldiers Memorial Military Museum in St. Louis, American stone ensures these sacred commemorative spaces preserve our most treasured memories in materials worthy of such honor.

The enduring strength and natural beauty of American granite and marble make these materials the preferred choice for memorial projects nationwide. Whether honoring individual veterans in local communities or creating grand national monuments in Washington D.C., our domestic stone quarries provide the premium materials and craftsmanship that memorial designers demand. By selecting high-quality stone from Polycor’s trusted American quarries, communities can rest assured they are getting only the best materials for monuments that will continue to stand as symbols of remembrance and inspiration for centuries to come.

American Stone Resources

Technical Support and Documentation

Our American operations provide comprehensive technical support, including detailed specification data sheets, installation guides, and ASTM testing data for every stone we quarry. This domestic expertise ensures that architects and specifiers have immediate access to the information they need.

Educational Resources

- Installation Training: Hands-on education from skilled craftsmen

- Quarry Videos: See how American stone is extracted and processed

- Interactive Virtual Tours: Explore our Cambrian Black quarry operations

- Technical Webinars: Learn from American stone experts

Design Tools and Support

American stone projects benefit from comprehensive design support, including:

- BIM Objects: Detailed 3D models for major American stones

- CAD Files: Precise technical drawings for specification

- Sample Programs: Physical samples of American stones

- Expert Consultation: Direct access to American stone specialists

- Stone Spec Sheets: Access all the testing data for each stone

Ready to Use American Stone in Your Next Project?

Ready to discover how American stone can transform your next project? Our stone experts are available to assist you in selecting the optimal materials and help ensure your project stays on schedule. From reduced lead times and predictable costs, to exceptional quality and reliable availability, American stone delivers advantages that imported materials simply cannot match.

Contact our American stone experts today to discover how domestic production can enhance your project’s timeline, budget, and quality standards. When you choose American stone, you’re selecting not only premium materials but also a partner dedicated to your success.