How American Stone Keeps Tradition Alive in the Heart of Washington D.C.

In Washington D.C., modern and historic live side-by-side, sometimes in the same building.

In the capital city’s Sixteenth Historic District, New York-based firm Robert A.M. Stern Architects, LLP(RAMSA) were tasked with designing a nine-story, 142,000-square-foot, mixed-use building. The future home to brand new ground-level shops, offices and The First Church of Christ Scientist, 900 16th Street also boasts spectacular views of the Washington Monument and White House from its ninth floor terrace.

The original, now demolished, brutaliststyle building by I.M Pei & Partners built in 1971.

In an area that is as prominent as it is diverse, the centrally located building is a proud combination of both forward thinking and historic American ideals. Not only would its design speak volumes, but it would impact a bustling neighborhood and busy street corner as well.

So, when it came time for RAMSA to specify material selections for the building’s exterior, it was clear that it would need to have the look and feel of days gone by, as well as a nod to the city’s ever-evolving future. The team worked with stone contractor R.Bratti whose solution to honoring Washington D.C.’s traditional palette of light-colored stone, without sacrificing a fresh and modern look, was historic GEORGIA MARBLE-WHITE CHEROKEE™marble paired with INDIANA LIMESTONE – FULL COLOR BLEND™. After all, this was to be a place of business, entrepreneurism and religion (melting pot, anyone?).

Street level elevations include White Cherokee® marble

Originating from Polycor’s extensive centuries-old quarries, American marble and domestic limestone are a natural fit for the nation’s capital having informed the city’s changing architectural fabric. Stylish and homogeneous, White Cherokee® is commonly used in large scale architectural projects and American heritage building restorations across the country — including notable monuments such as the Lincoln Memorial, and many others around town. Indiana Limestone is also a staple in and around the downtown district. At 900 16th St., RAMSA collaborated with Cooper Carry Architects incorporating thousands of square feet of these beautiful stones in a low-honed finish, reflecting the iconic look in the storefronts that welcome the curious passerby and employees on their lunch breaks. The building’s main panels are 2’ x 3’ x 2” thick and the windows above are also framed in 4’ x 6” x 3” moldings of cut to size White Cherokee marble, set into an Indiana limestone grid.

Another truly stunning feature to note is the crystalline interpretation of Gothic pinnacles sculpted in glass that function as the entrance to the new First Church of Christ Scientist. The gleaming geometric structure set against the creamy White Cherokee and buff limestone facade makes the marble’s silvery veins pop and compliments the companion material. Says RAMSA Project Architect Breen Mahony, “It was our intent to build upon and contribute to the strong and lasting tradition White Cherokee marble has in Washington D.C. on a number of meaningful buildings. And orienting the silvery veins of the stone in a consistent manner, so they slip across the building’s façade in a natural way, that was very important to us.”

It’s in the tiny details such as those that make White Cherokee so wonderfully dynamic. At first glance, the classic style and timeless look of the building’s marble exterior allows it to blend in seamlessly with the historic core of Washington D.C. However, as you get closer its natural variations and intricate designs offer visual interest without being overwhelming or distracting.

In an effort to capture the rich and historical quality of the marble, Breen and his team took a visit to the Polycor quarry in Tate, Georgia to see the stone up close and inspect the production capabilities at the plant.

“When you clad a building in a marble that has a prominent vein, you’re trying to create a storyline – a narrative, so as the stone is set into the façade and as it negotiates corners and changes in plane, how the stone’s character is revealed and celebrated is of fundamental importance in creating that narrative,” Breen said.

Stone selection during the quarry visit was an important design element. Breen and his team were able to hand-pick the stone and determine the orientation of the veining so that it ran continuously from lower left to upper right diagonally for a more monolithic, continuous appearance.

“You really need to be thorough when researching a stone to best understand how it’s character can change within a given block and how those changes are manifest in individual slabs,” says Breen. “A visit to the quarry presents a great opportunity — not only for us — but for the owner and developers of the building, the construction manager and of course Polycor […] to discuss expectations and opportunities in translating the stone into the cladding material for the actual building.”

Implementing best practices for a sustainable design throughout the building such as energy-saving mechanical systems, a green roof with native vegetation and low-VOC materials helped 900 16th St earn a LEED Gold Certification from the U.S. Green Building Council (USGBC). Contributing significantly to the LEED Gold status of the project was the use of locally-quarried White Cherokee marble and Indiana Limestone – Full Color Blend in the design.

What made this project even more unique was not only the selection, but the execution and cutting of the stone. In order to be as efficient as possible, the stone was cut to size at the quarry and the finished pieces were then attached to precast panels off-site, ensuring a smooth and seamless construction process.

The team worked with a Virginia-based architectural precast concrete company, Arban & Carosi, whose unique solution was instrumental in completing the project on budget and on time. Nick Carosi, whose family has been in the business for over 90 years, commented on the challenges he and his team faced, “The modeling of the project was tremendously challenging. The exposed faces of the marble were articulated as well as their rear surfaces. The precast backup for the cladding had to fill in precisely to avoid gaps or voids which would have thrown off material estimates and other precast parameters such as weight.”

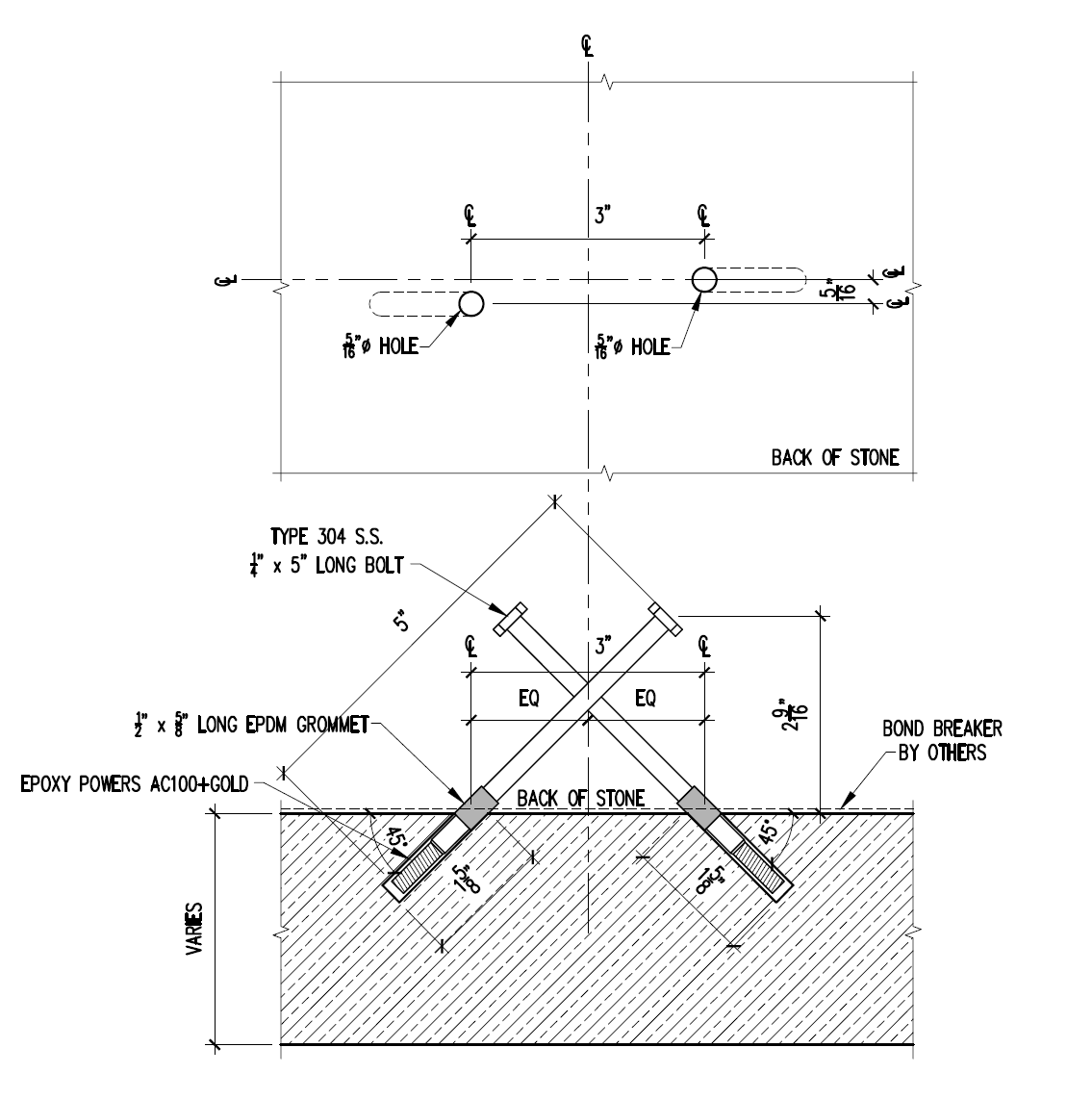

Anchor detail illustrating marble panel & precast bolt connection. Image courtesy of R.Bratti.

“They’re quite good and do have a pretty unique process in forming their panels”, said Mahony on working with Arban & Carosi, “I think one of the challenges of working with precast panel is how you panelize a building in a manner that achieves that construction’s efficiency, but when you step back and look at the building it doesn’t look like a panelized building.”

READ MORE ABOUT POLYCOR STONE FACADE SYSTEMS HERE

“You don’t want to lose the richness of stone cladding and the scale of the various components of stone stacked,” he said. “That’s a very meaningful relationship between the viewer and the building. I think it’s a very thoughtful process not just on our end, but also on the contractor’s end and the stone fabricators end”. Contractor R. Bratti performed the bulk of the work behind the scenes and on site in the field to execute the design as planned.

The combination of modern fabrication processes, creative architecture and historic natural stone allowed 900 16th St. to stay firmly rooted in the past while looking ahead to the city’s future. “We wanted to give the building a sense of place”, remarked Breen, “and keep with the rich tradition of [Georgia marble] in D.C.”