Polycor U

Go Big! How to Install XL Granite Slab Pavers

You know the saying, “Go big or go home.” Now you can go big AT home! With extra large, natural stone pavers, you can enhance entrances, walkways, and patios, boosting your home’s curb appeal and resale value. Cover more square footage with fewer pavers and give your outdoor space a clean, contemporary look. These large format pavers give areas a seamless, unifying effect that makes any space feel immediately larger.

Course Description

In this video, we’ll demonstrate two methods for installing 36” x 36” x 1 1/2″ thickness XL Bethel White granite pavers – open graded base and wet setting into a mortar bed. With natural stone, it’s easy to go larger format than with precast products because of their greater density and flexural strength.

Want to learn more about Polycor Large Pavers? Read more in this in-depth article, New Ways To Go Big With Large Stone Pavers..

How To Install XL Granite Slab Pavers: Go Big or Go Home

The phrase “go big or go home” takes on new meaning when applied to outdoor hardscaping. With Polycor’s XL natural stone pavers, you can literally go big at home, transforming entrances, walkways, and patios with dramatic oversized stones that make an immediate visual impact while boosting your property’s curb appeal.

Beyond their striking appearance, XL pavers offer practical installation advantages that make them appealing to both contractors and homeowners. These large stone pavers cover significantly more area in less time—you can lay eight or nine square feet in just 30 seconds compared to the extended time required for standard format pavers to cover the same space. This efficiency translates to faster project completion and reduced labor costs.

Size Options and Material Choices

Polycor’s XL pavers are available in two generous sizes: 36″ x 36″ and 24″ x 48″, offered in granite, limestone, and marble. Each material brings distinct characteristics to your project. Granite provides exceptional durability and a wide range of colors, limestone offers timeless appeal with natural earth tones, while marble delivers luxury aesthetics with distinctive veining patterns.

For this installation demonstration, we’ll focus on 36″ x 36″ Bethel White granite pavers sourced from Polycor’s Vermont quarry. This particular granite showcases the clean, bright appearance that makes white granite so popular for contemporary outdoor designs.

Installation Method One: Open Graded Base System

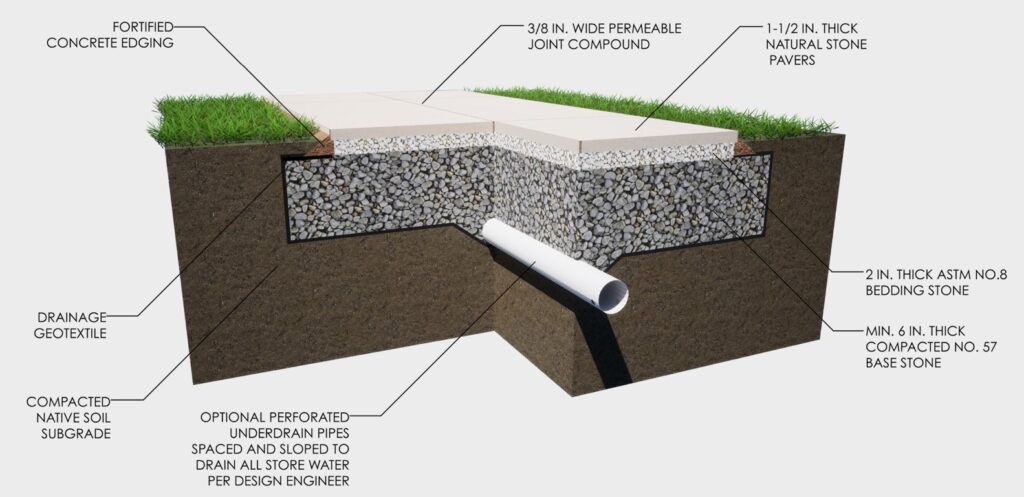

The open graded base system represents modern thinking in paver installation, providing superior water management through enhanced permeability. This method directs rainwater down into the subsoil rather than creating surface runoff, making it environmentally responsible while protecting your installation from water-related damage.

Site Preparation

Begin by laying out your space using string lines to establish precise boundaries and alignment. For new construction projects, you can proceed directly to excavation. However, existing homes require calling 811 prior to any excavation to mark utility cables and wires—a critical safety step that prevents dangerous and expensive accidents.

Excavate to a depth of 8-10 inches, maintaining proper dimensions throughout the area. The recommended base thickness for walkways and patios ranges from 6-8 inches minimum, providing adequate support for the substantial weight of XL pavers. During excavation, establish and maintain a slope of 3/16″ per foot away from your home’s foundation for proper drainage. This slope must be preserved throughout the entire installation process.

Extend your excavation beyond the planned paver edges by the thickness of your base material. This extra space accommodates edge restraints and ensures complete support for perimeter pavers.

Base Construction

Line the excavated area with geotextile membrane to prevent soil migration into your stone base while still allowing water passage. This barrier maintains the integrity of your base system over time.

Begin spreading ASTM No. 57 stone (¾” crushed stone) in lifts of 2-4 inches. Lightly moisten each lift before compacting with a plate compactor, checking frequently to ensure your drainage slope remains consistent. The quality of aggregates varies by geographical region—some areas provide more angular stone while others offer more rounded pieces. Both can achieve proper compaction when handled correctly.

Continue building your base until reaching the desired thickness, typically 6-8 inches of compacted material. Next, spread a 1-inch layer of ASTM No. 8 stone (⅜” clean, angular stone). Use 1-inch diameter pipes as screed guides to establish proper grade, then screed the surface smooth. Remove the pipes and fill any resulting voids for a perfectly level bedding layer.

Paver Installation with Modern Equipment

The substantial size and weight of XL pavers make manual handling challenging and potentially dangerous. Professional pavers installation increasingly relies on vacuum lifting equipment to position these large stone pavers safely and precisely. The MQuip MK2 vacuum lifter, with its 3,000-pound capacity, proves ideal for natural stone installations of this scale. Other comparable vacuum lifters can be found at local tool rental stores to rent by the day and will greatly improve efficiency.

Begin laying pavers according to your design, typically working from the centerline of doorways outward toward adjoining walls. Use ⅜” spacers to maintain consistent joint spacing between pavers. Check that each paver sits flush with adjacent stones while maintaining the proper drainage slope established during base preparation.

Complete the installation by filling joints with a permeable product such as EZ-Joint by Azpects. This, and other comparable jointing materials, allow water to continue draining through the system while providing joint stability and weed prevention.

Installation Method Two: Wet Setting in Mortar

The wet setting method creates a more rigid installation suitable for areas requiring maximum stability or where permeability isn’t a primary concern. This traditional approach bonds pavers directly to a mortar bed for permanent placement.

Modified Base Preparation

Excavate to the same 8-10 inch depth as the open graded method, but construct a reduced base of only 4-6 inches using ASTM No. 57 stone. Spread the crushed stone in 2-inch lifts, moistening and compacting each layer while maintaining proper slope for drainage.

Mortar Bed Construction

Create your mortar mixture using Portland cement, sand, and water in approximately an 8:1 ratio. The consistency should be fairly dry—when squeezed in your hand, no water should drip through your fingers. This dry mix provides better support and prevents settling during curing.

Prepare a slurry bond coat using 1-2 parts Portland cement to 1 part water in a 5-gallon bucket. This slurry creates superior adhesion between the dry mortar bed and the paver.

Spread the dry mortar mix evenly over your compacted aggregate base. Lay heavy wire mesh over the mortar and embed it into the center, adding another layer of mortar over the top. This reinforcement prevents cracking and provides additional structural support for the heavy XL pavers.

Setting the Pavers

Using a cup or ladle, pour slurry bond coat evenly onto the mortar bed surface. Carefully position each paver using your vacuum lifter, then tamp as needed to embed the stone and achieve level placement. The substantial weight of XL pavers helps them settle into the mortar bed naturally.

Complete the installation by mortaring the joints with approved masonry mortar, creating a completely rigid surface that can handle heavy traffic and severe weather conditions.

Design Considerations for XL Pavers

The large format of XL pavers creates unique design opportunities while presenting specific challenges. Their substantial size makes dramatic visual statements, particularly effective in contemporary and minimalist designs where clean lines and uninterrupted surfaces are desired.

Consider how the scale of XL pavers relates to your overall space and architectural elements. While they create impressive impact in large areas, they can overwhelm smaller patios or narrow walkways. The 24″ x 48″ rectangular format often works better in linear applications like walkways, while the 36″ x 36″ square format excels in patio and seating areas.

Joint patterns become more prominent with large format pavers, making precise installation critical for professional appearance. The reduced number of joints compared to smaller pavers simplifies maintenance while creating cleaner sight lines.

Material Handling and Safety

The substantial weight of XL pavers—often exceeding 200 pounds each—demands respect and proper handling techniques. Never attempt to move these stones manually without appropriate equipment. Vacuum lifters, stone clamps, or small machinery prevent injury while ensuring precise placement.

Plan your material delivery carefully, positioning pavers as close to their final location as possible. The fewer times you handle these heavy stones, the safer and more efficient your installation becomes.

Maintenance and Long-Term Performance

XL pavers offer exceptional longevity when properly installed, with minimal maintenance requirements. The reduced number of joints means less opportunity for weed growth and easier cleaning. Periodic joint sand replenishment may be needed for open-grade installations, while mortared installations typically require no routine maintenance.

The thermal mass of large format stones helps moderate temperature swings, potentially reducing freeze-thaw stress in cold climates. However, ensure proper drainage in all installations to prevent water accumulation that could cause problems during freezing weather.

When to Choose XL Pavers

XL pavers excel in applications where dramatic visual impact and quick installation are priorities. They work particularly well for:

- Large patios and entertainment areas where their scale creates impressive focal points

- Modern architectural settings that emphasize clean lines and minimal joints

- Commercial applications requiring durability with reduced maintenance

- Projects where installation speed provides significant cost savings

Consider standard format pavers for intricate patterns, smaller spaces, or installations requiring extensive cutting and fitting around complex boundaries.

Professional Results with Premium Materials

Installing XL pavers successfully requires understanding both their potential and their demands. Proper base preparation, appropriate paver installation methods, and respect for their substantial weight ensure results that showcase these impressive natural stones to their best advantage.

The investment in XL pavers pays dividends through their dramatic visual impact, installation efficiency, and exceptional longevity. When you’re ready to make a statement with your outdoor hardscape, going big with Polycor’s extra large pavers delivers results that truly stand apart.

Ready to transform your outdoor space with the impressive scale and beauty of XL granite slab pavers? Contact a Polycor expert today to explore which XL paver options work best for your specific project requirements and design vision. Professional guidance ensures you achieve both the immediate impact and long-term performance that make XL pavers such a compelling choice for discerning property owners.